5-axis machining is supposed to reduce setups—but many shops hit the same wall: tool access. You can have a great machine and great CAM, then lose time because the spindle can’t approach features safely without collisions or awkward long tools. That’s why pyramid-style fixtures keep showing up in modern 5-axis workholding: they solve access problems mechanically, not just digitally.

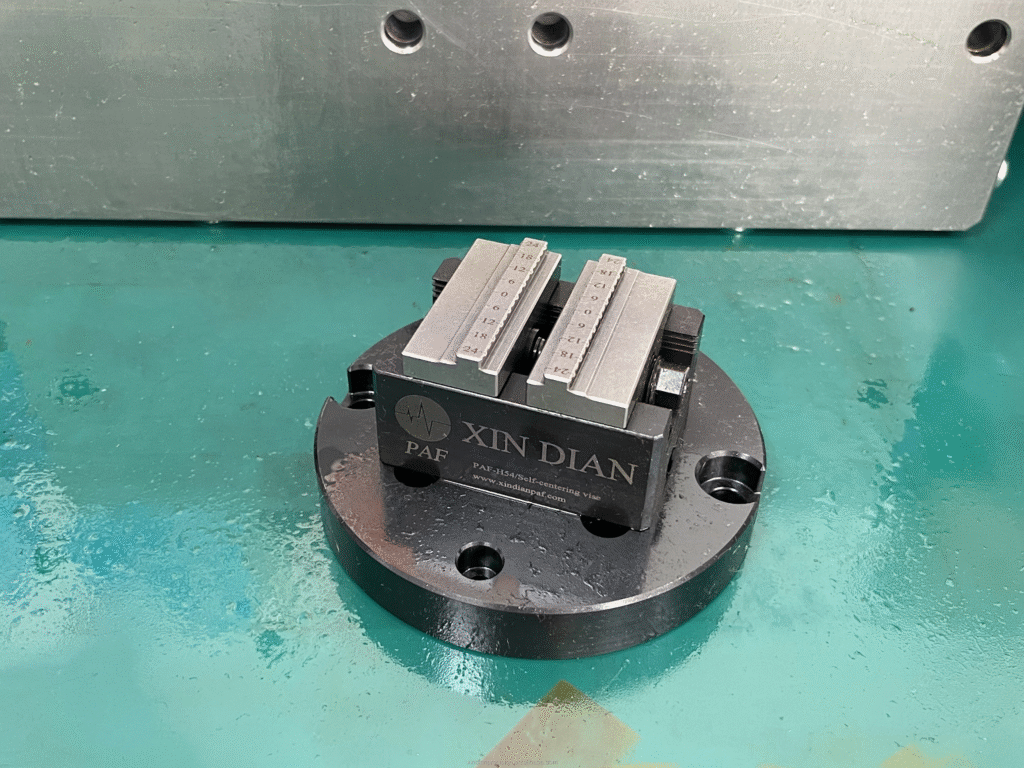

A three-sided pyramid fixture is designed to support multi-part loading and create more reachable machining angles in one clamp. Xindian’s description of its three-sided pyramid emphasizes exactly that: greater access for 5-axis applications, with a 20° mounting surface that provides more clearance between spindle/toolpath and the fixture, allowing more machining per clamp.

What a pyramid fixture actually changes

A normal hydraulic vise setup tends to keep parts “flat” to the table. That’s fine until you need real 5-axis motion: tilting the table and rotating the part often pushes the toolholder into the vise body, the table, or the fixture itself. The pyramid approach changes the geometry by giving you angled faces to mount parts, so the part is already positioned in a more accessible orientation before the machine even starts moving.

Why the 20° angle is a practical advantage

That 20° mounting surface isn’t a random number—it’s a clearance strategy. The benefits tend to show up as:

- Fewer collisions and fewer “near misses.” More clearance between spindle and cutting path means fewer forced retracts and fewer cautious edits mid-run.

- Shorter tools (often). When access is better, you can avoid overextending tools just to clear the fixture—shorter tools usually mean better rigidity and finish.

- More machining per clamp. If you can reach more faces without re-clamping, you reduce setup time and reduce stack-up error across operations.

- Better density for small parts. A three-sided design naturally supports multi-part loading, which can increase throughput for repeatable components.

Where pyramid fixtures shine

If you’re deciding whether a pyramid fixture is “worth it,” these are the best-fit scenarios:

- Parts with features on multiple faces (holes, ports, pockets, angled surfaces) where re-clamping adds time and risk.

- Small-to-mid parts you can run in batches, where multi-part loading makes cycle time worth planning.

- Work where toolholder collisions are already your bottleneck, and CAM workarounds (long tools, weird approach angles) are lowering stability.

- High-mix shops that want a repeatable workholding “shape” they can return to quickly.

How to start using a pyramid fixture without overcomplicating it

Keep the rollout simple—pyramid fixtures work best when you treat them like a standardized base for repeat routines.

- Pick one part family (not ten). Choose a part where access is currently painful.

- Standardize your mounting approach. Use the same side/face orientation every time for that part family.

- Build a “safe tool library” for that setup. Your goal is fewer special tools and fewer long tools.

- Define a probing routine once and reuse it—this is where “more machining per clamp” becomes real shop time saved.

- Document the fixture plan (which face, which stops, which torque habits). Repeatability comes from habits, not just hardware.

Common mistakes (and how to avoid them)

- Overloading the pyramid with too many unique parts at once. Multi-part loading is powerful, but it becomes chaotic if every part requires a different strategy.

- Ignoring chip control. More faces and pockets can mean more chip traps—plan air blast/coolant flow early.

- Treating the pyramid like a vise. A pyramid is an access tool—if you mount parts like a flat 5th axis vise , you’ll miss most of the advantage.

- Skipping clearance checks. The 20° mounting surface helps, but you still need a fast collision sanity check for each new part/fixture combo.